The first time a factory owner notices a seam failure is rarely dramatic. It happens quietly: a returned garment, a customer email, a product review that hints at disappointment. On the surface, the issue seems minor—a thread coming loose, a hem curling after washing. Yet beneath that small flaw lies a bigger truth. Seams are not just stitches. They are structural decisions. In manufacturing, fashion, upholstery, and even technical textiles, Nahttypen define how a product performs, how long it lasts, and how customers experience quality without ever consciously seeing it.

For entrepreneurs, product designers, and tech-driven founders entering physical production, understanding Nahttypen is not a craft detail—it is a strategic advantage. Seams translate design ideas into durable reality. They determine whether a product survives stress, motion, time, and repeated use. In an age where materials innovate rapidly, seam construction remains one of the most overlooked yet decisive elements of product engineering.

Why Nahttypen Matter More Than You Think

Every physical product experiences tension. Clothing stretches with movement, bags carry weight, upholstery absorbs pressure, and industrial textiles face heat, friction, or moisture. Nahttypen define how that tension is distributed. A poorly chosen seam concentrates stress at a single line, inviting failure. A well-chosen seam disperses force across layers, extending product life.

From a business perspective, seam selection directly impacts return rates, warranty claims, and brand reputation. Customers may not know the name of a seam, but they recognize quality instinctively. When seams lie flat, resist fraying, and hold shape after repeated use, trust is built silently. When they fail, trust erodes just as quietly.

The Evolution of Seams in Modern Production

Historically, seams were shaped by necessity and available tools. Early hand-sewn garments relied on simple constructions because time and labor were limited. Industrialization changed that equation. Sewing machines introduced consistency, speed, and the ability to layer fabrics in new ways. Over time, Nahttypen evolved to meet increasingly specialized demands, from flexible sportswear to rigid safety gear.

Today, seam construction reflects a balance between aesthetics, performance, and efficiency. Automated production lines favor seam types that maintain precision at scale, while premium products invest in more complex seams that signal craftsmanship. Understanding this evolution helps founders align seam choices with brand positioning.

Core Categories of Nahttypen Explained

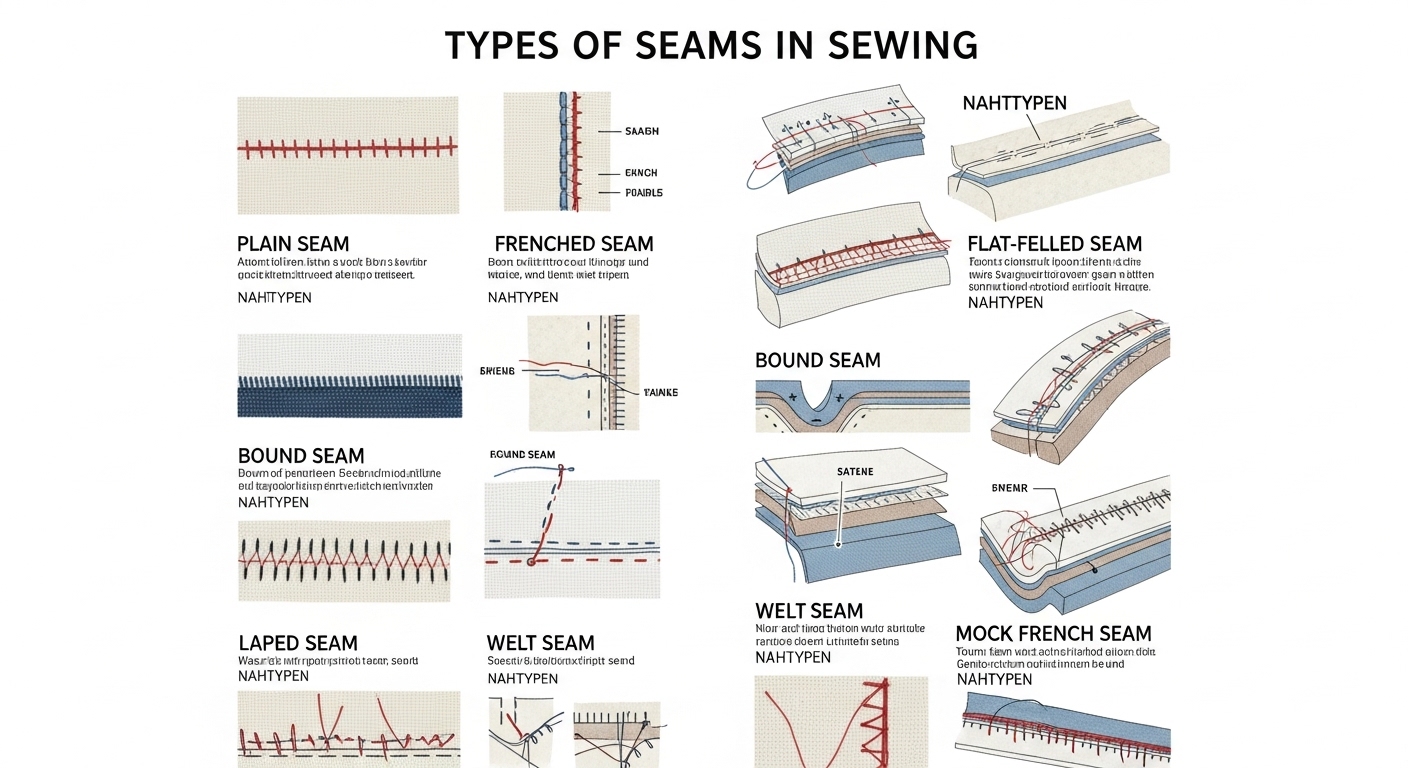

Nahttypen can be grouped by how fabric layers interact. Some seams join edges directly, others overlap materials, and some encase raw edges for durability. Each category serves a distinct purpose, and misapplying them often leads to premature wear or discomfort.

Plain seams remain the foundation of many products. They are efficient, easy to produce, and suitable for low-stress areas. Their simplicity, however, demands proper finishing to prevent fraying. Lapped seams, where one fabric overlaps another, offer greater strength and are common in workwear and leather goods. Enclosed seams protect raw edges entirely, making them ideal for garments that face frequent washing or direct skin contact.

The choice among these Nahttypen is rarely about right or wrong. It is about context. Fabric type, product use, and target customer all influence the optimal solution.

How Seam Selection Impacts Comfort and User Experience

Comfort is often treated as a fabric issue, but seams play an equally critical role. Bulky seams create pressure points, restrict movement, and irritate skin. Flat seam constructions reduce thickness and friction, making them essential in sportswear and performance apparel.

In consumer products, seam comfort translates directly into perceived quality. A technically advanced fabric can feel inferior if seam placement and construction disrupt wearability. For founders entering wearable technology or smart textiles, seam design becomes even more complex, as it must accommodate sensors, wiring, or conductive threads without compromising comfort.

Nahttypen in High-Stress and Technical Applications

Beyond fashion, Nahttypen are vital in technical fields. Outdoor gear, medical textiles, and automotive interiors all rely on seams engineered for extreme conditions. In these contexts, seam failure can mean more than dissatisfaction—it can pose safety risks.

Reinforced seams distribute load across multiple stitch lines, increasing tensile strength. Welded or bonded seams, increasingly common in waterproof products, eliminate needle holes altogether. These advanced Nahttypen demonstrate how seam construction adapts as performance demands increase.

Balancing Cost, Speed, and Quality in Seam Decisions

For entrepreneurs, every production decision carries financial implications. Complex seams require more machine time, skilled labor, or specialized equipment. Simple seams reduce costs but may limit durability or comfort. The art of seam selection lies in aligning product expectations with manufacturing realities.

A startup producing everyday apparel may prioritize efficiency, selecting Nahttypen that balance durability with scalability. A premium brand may justify higher costs through superior seam construction that reinforces its value proposition. In both cases, informed decisions prevent costly redesigns and production delays.

Common Nahttypen and Their Practical Applications

The table below highlights widely used Nahttypen and where they excel. While not exhaustive, it provides a practical reference for aligning seam choice with product requirements.

| Nahttyp | Structural Characteristic | Typical Application |

|---|---|---|

| Plain Seam | Simple edge-to-edge join | Casual garments, linings |

| French Seam | Enclosed raw edges | Lightweight fabrics, luxury apparel |

| Flat Seam | Minimal bulk, smooth finish | Sportswear, underwear |

| Lapped Seam | Overlapping fabric layers | Leather goods, workwear |

| Reinforced Seam | Multiple stitch lines | Outdoor gear, load-bearing areas |

This overview shows that Nahttypen are less about tradition and more about function. Each seam type reflects a response to a specific challenge.

Sustainability and the Role of Seam Construction

As sustainability becomes central to product strategy, Nahttypen gain new relevance. Durable seams extend product life, reducing waste. Repair-friendly seams support circular design by allowing garments to be altered or mended rather than discarded.

Some seam constructions also affect recyclability. Seams that combine incompatible materials or excessive adhesives complicate recycling processes. Forward-thinking brands now consider seam design as part of their environmental responsibility, choosing Nahttypen that align with long-term sustainability goals.

Seam Innovation in the Age of Smart Manufacturing

Technology continues to reshape seam construction. Computer-controlled machines deliver consistent stitch quality at scale. Laser cutting improves seam alignment, while ultrasonic bonding introduces stitch-free alternatives. These innovations expand the definition of Nahttypen beyond thread and needle.

For tech-oriented founders, this opens opportunities to differentiate products through engineering rather than aesthetics alone. Seam innovation becomes a storytelling tool, communicating technical sophistication and attention to detail without overt marketing claims.

Mistakes to Avoid When Choosing Nahttypen

One of the most common mistakes is treating seam selection as an afterthought. Designing a product first and forcing a seam solution later often leads to compromises. Another frequent error is copying seam choices from visually similar products without understanding their functional context.

Expert insight suggests involving seam considerations early in prototyping. Testing seams under real-use conditions reveals weaknesses before mass production. This proactive approach saves resources and protects brand credibility.

The Strategic Value of Seam Literacy

Understanding Nahttypen empowers decision-makers. It bridges the gap between design intent and manufacturing execution. It also fosters clearer communication with suppliers, reducing misunderstandings that lead to inconsistent quality.

For founders scaling production, seam literacy becomes a form of risk management. It ensures that growth does not dilute product integrity. In competitive markets, where materials and designs can be replicated quickly, seam quality often becomes the silent differentiator.

Conclusion

Nahttypen rarely appear in marketing headlines, yet they shape every tactile interaction a customer has with a product. They hold together not just fabric, but trust, performance, and brand promise. For entrepreneurs and product leaders, learning to see seams as engineered solutions rather than technical details changes how products are conceived and delivered.

In a world obsessed with innovation, seams remind us that progress often lies in refining fundamentals. Mastery of Nahttypen is not about complexity for its own sake. It is about choosing the right structure, in the right place, for the right reason—and letting quality speak quietly through every stitch.